Fischer US, LLC is affiliated with the Austrian company Fischer Maschinen und Apparatebau GmbH (https://www.fischer-heatexchanger.com). This Austrian company was founded in the year 1933. It was one of the first manufacturers of Plate Heat Exchangers for the food industry which could establish itself successfully on the world market. Continuous research and development for products made by Fischer are still helping to safeguard their top position worldwide with regard to quality and reliability.

The company has maintained a strong position on the international market for many years. It is a particular goal to service their customers to their full satisfaction. The ample stock for spare parts comprises spare parts for all units and systems manufactured during the last decades. This ensures delivery of requested spare parts within a minimum of time. For start-up, service and maintenance especially trained technicians are available.

Fischer Facts:

- Established: 1933

- Location: Austria, Ebreichsdorf (near Vienna)

- One of the first manufacturers of Plate Heat Exchangers for the food industry

- Successful on the world market

- Continuous research and development for products

- Top position worldwide with regard to quality and reliability

Contact Us

the company is run by the brothers, Bernhard, Herbert and Harald Fischer (from left to right)

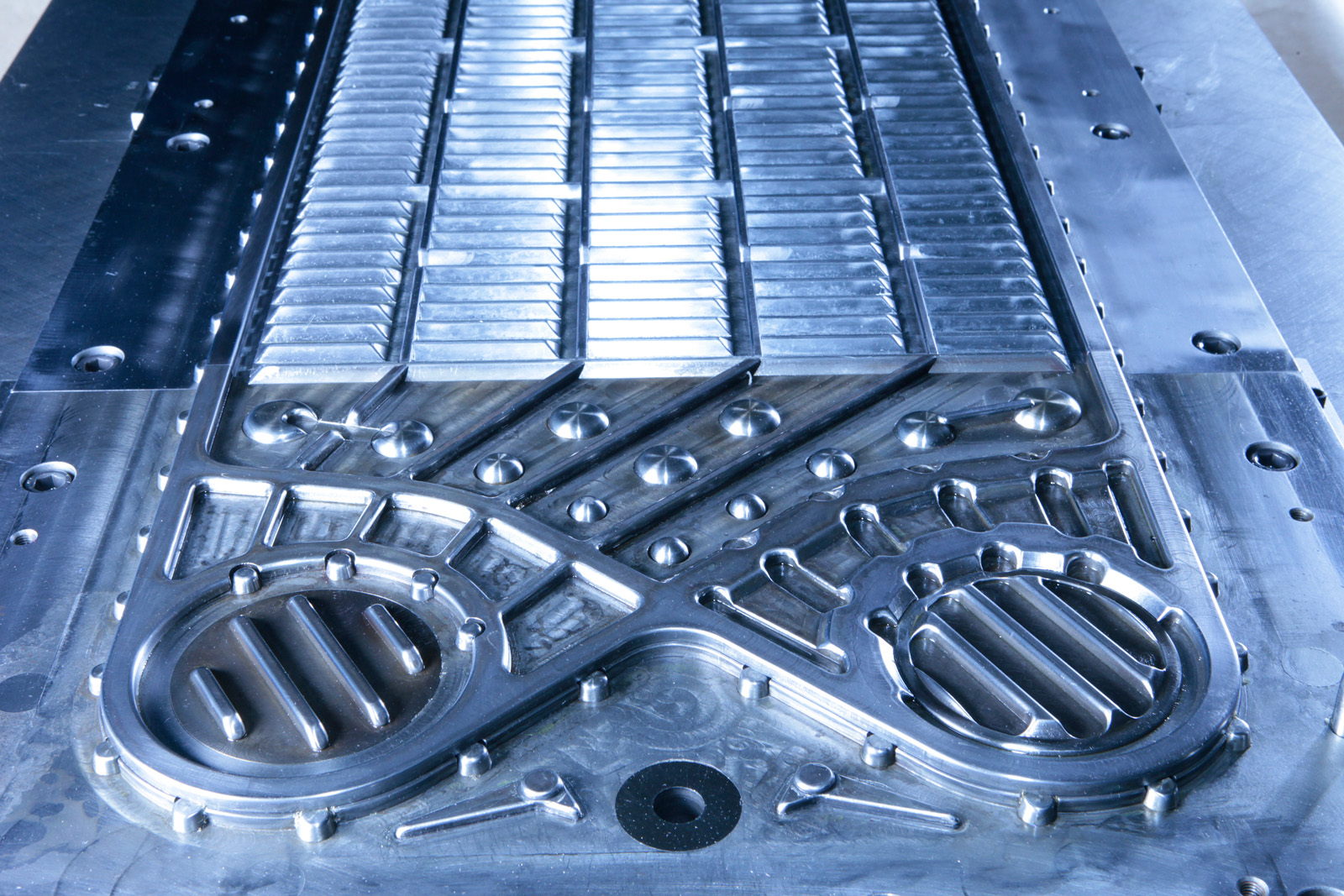

In-house development and design make it possible for us to produce the right heat exchanger for every thermal processing installation

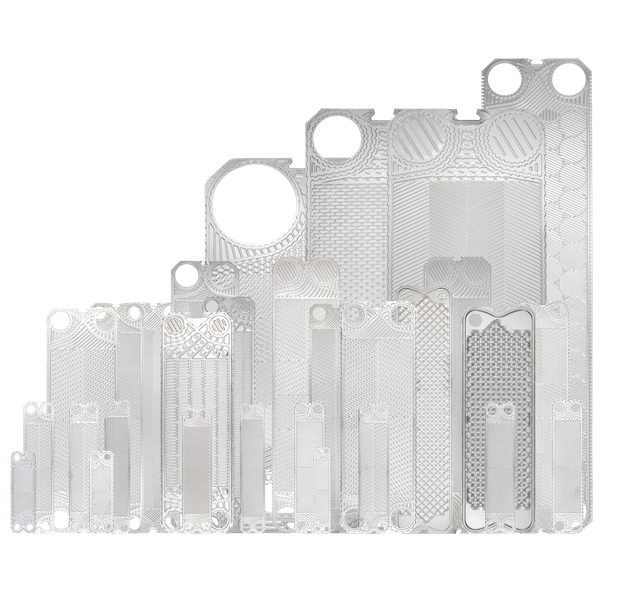

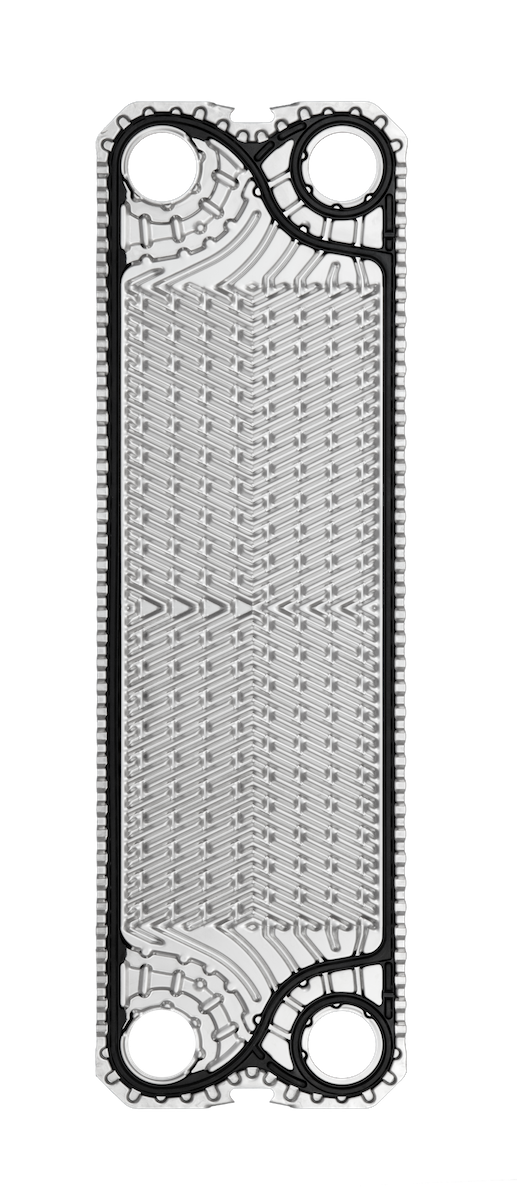

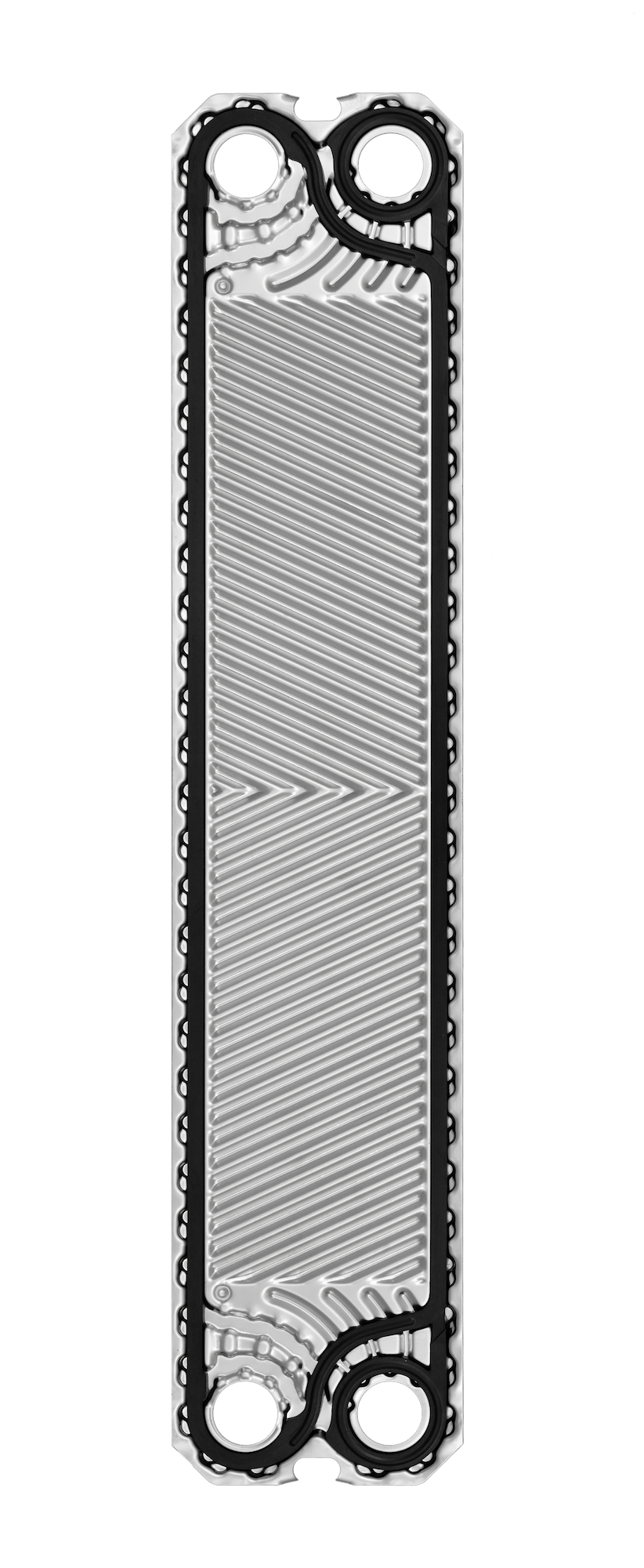

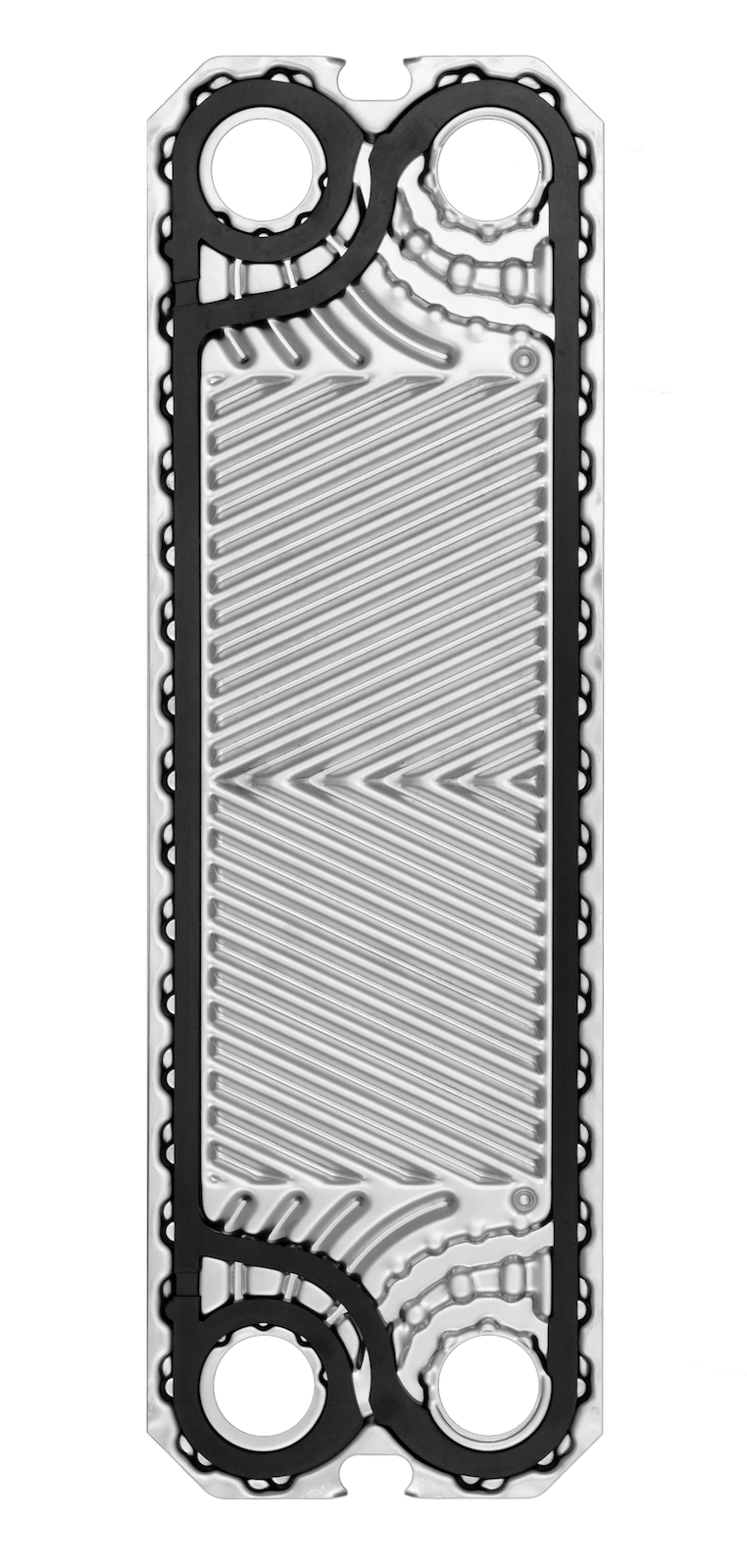

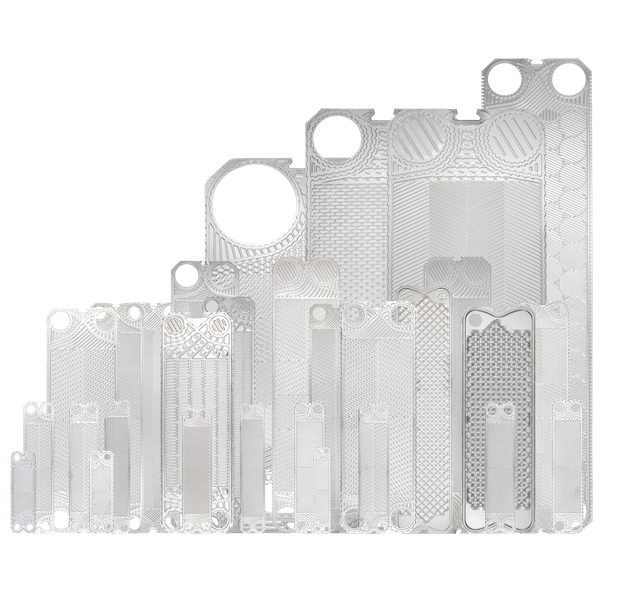

Choose from our extensive offerings to find the plate which fits your requirements best

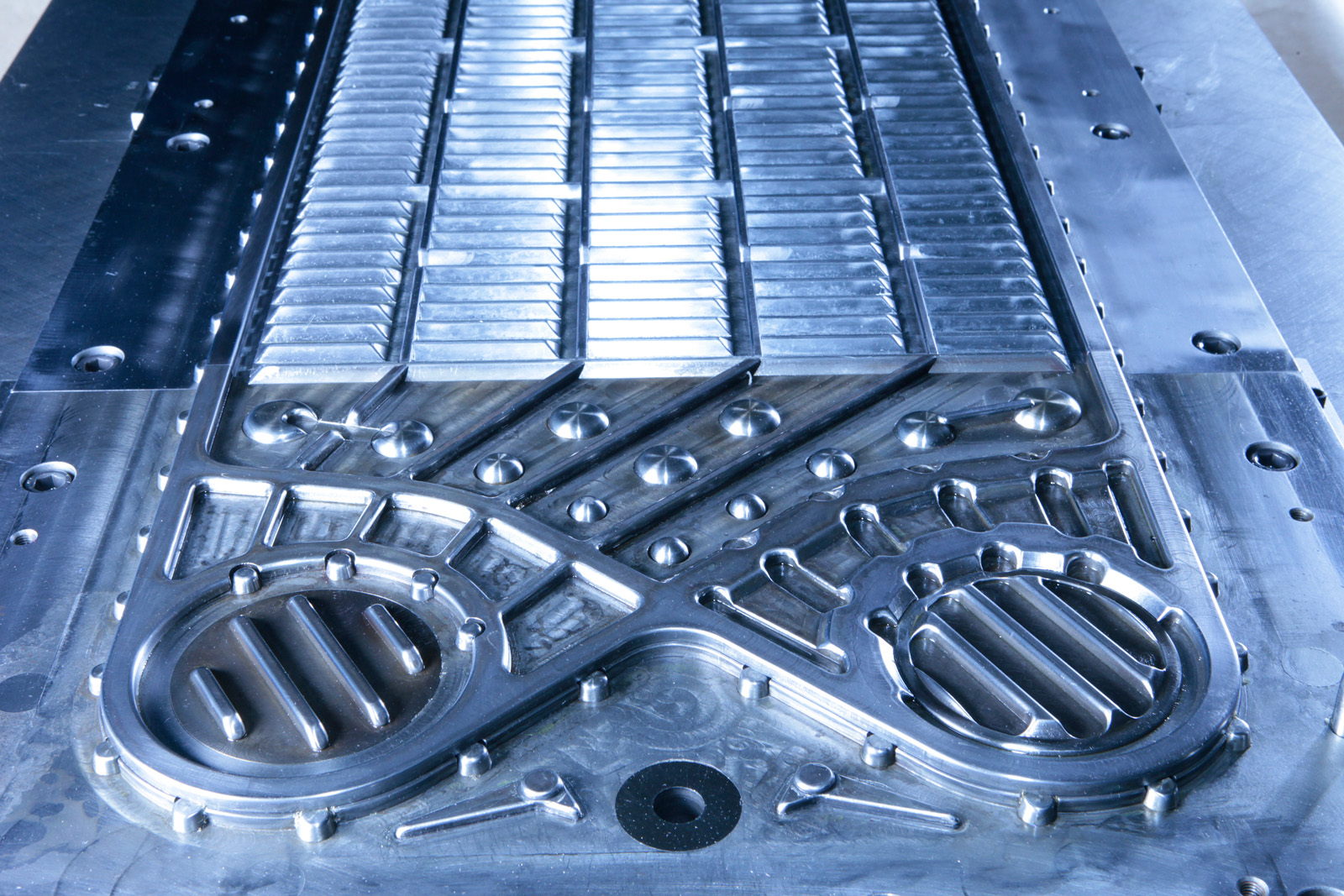

most modern manufacturing to assure our customers the highest quality, precision and reliability

Headquarters:

USA

Fischer-US LLC

1433 Westbrook Ave

Richmond, VA 23227

sales@fischer-us-llc.com

Austria

FISCHER Maschinen- u. Apparatebau GmbH

Linke Bahnzeile 22

2483 Ebreichsdorf

https://www.fischer-heatexchanger.com

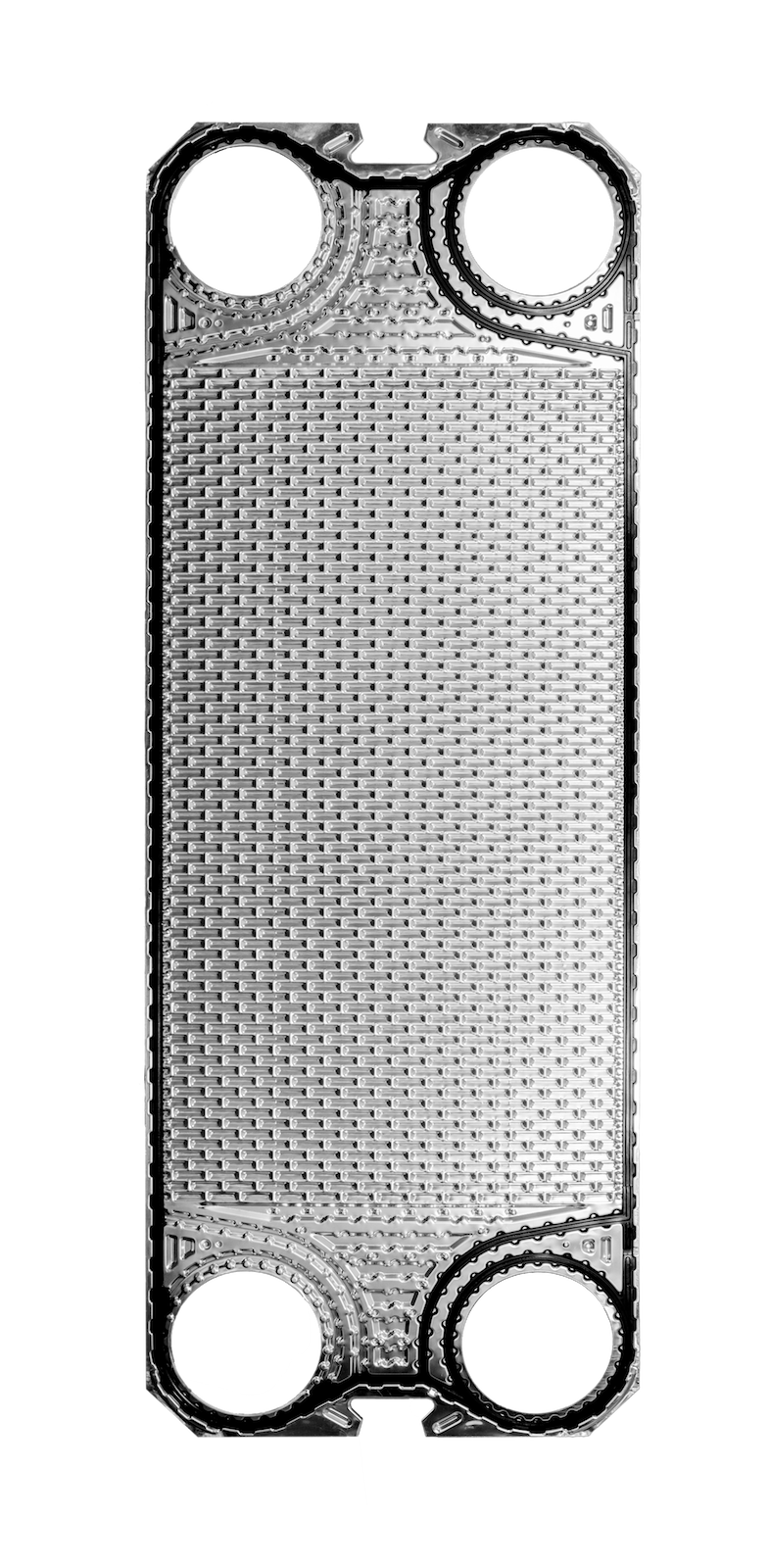

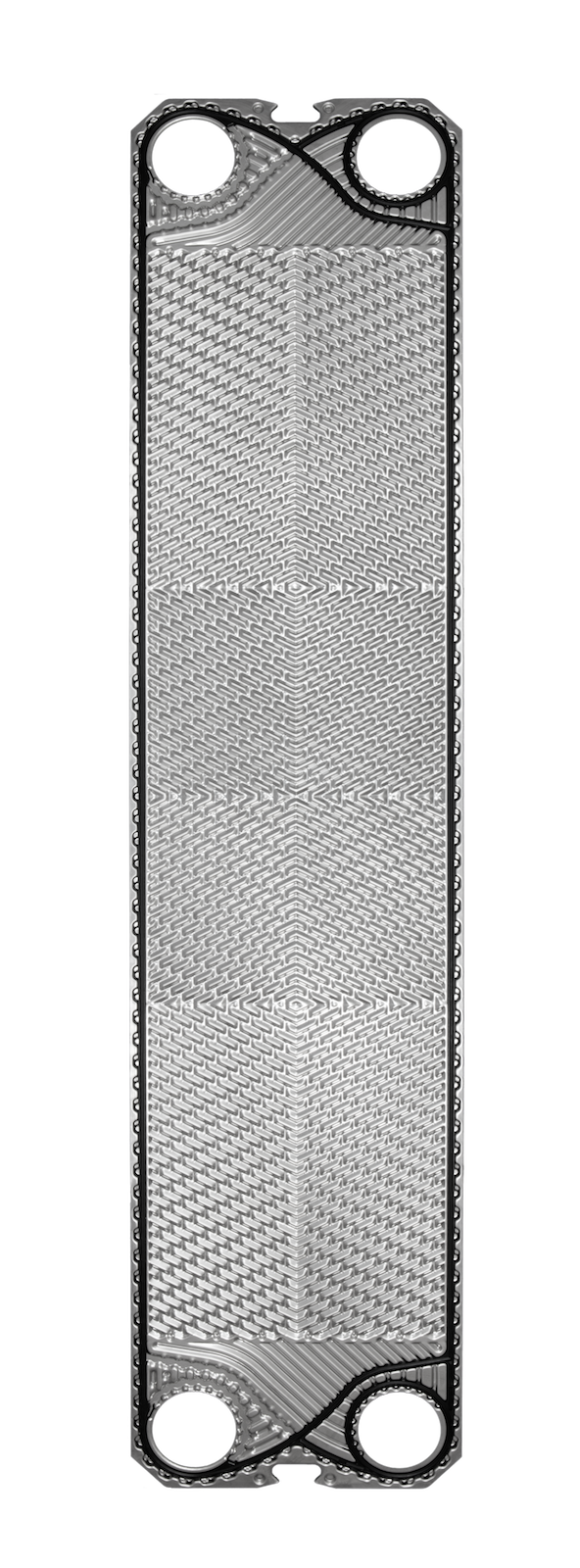

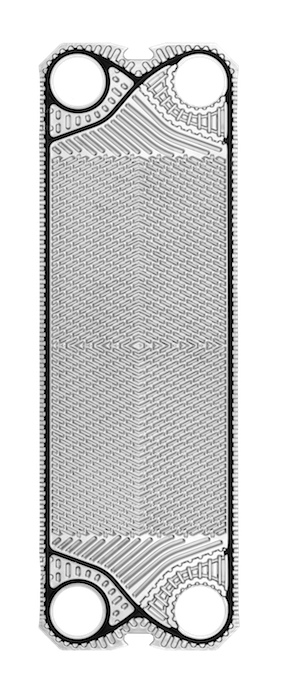

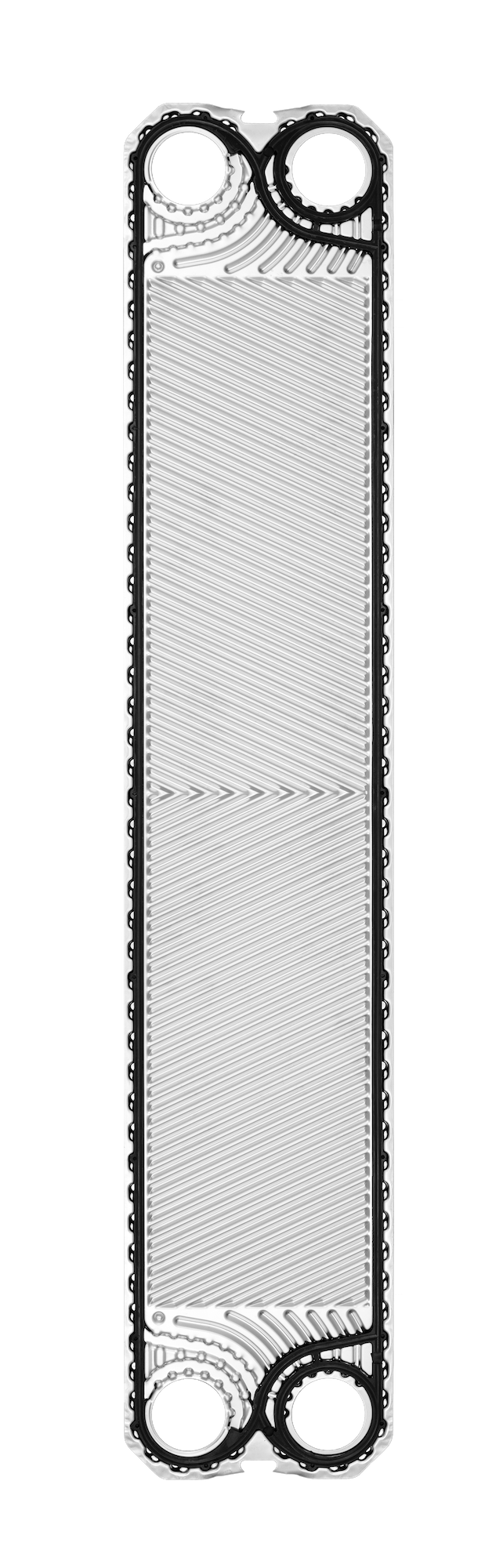

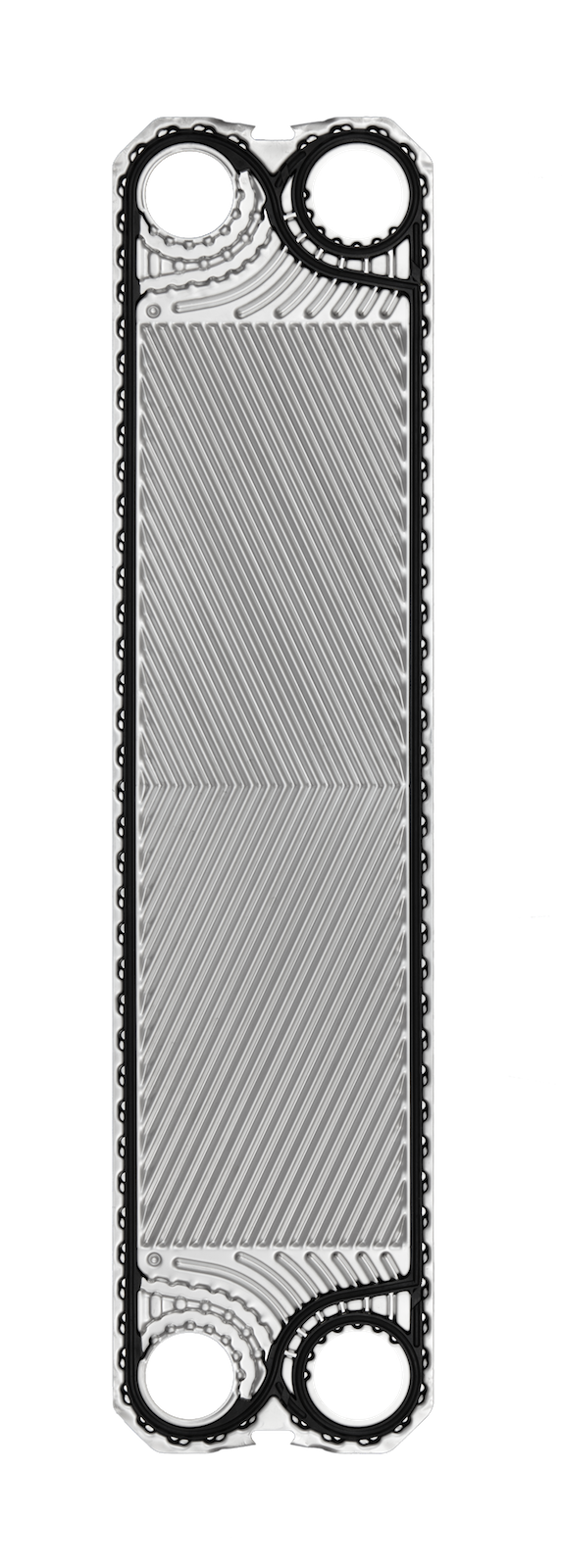

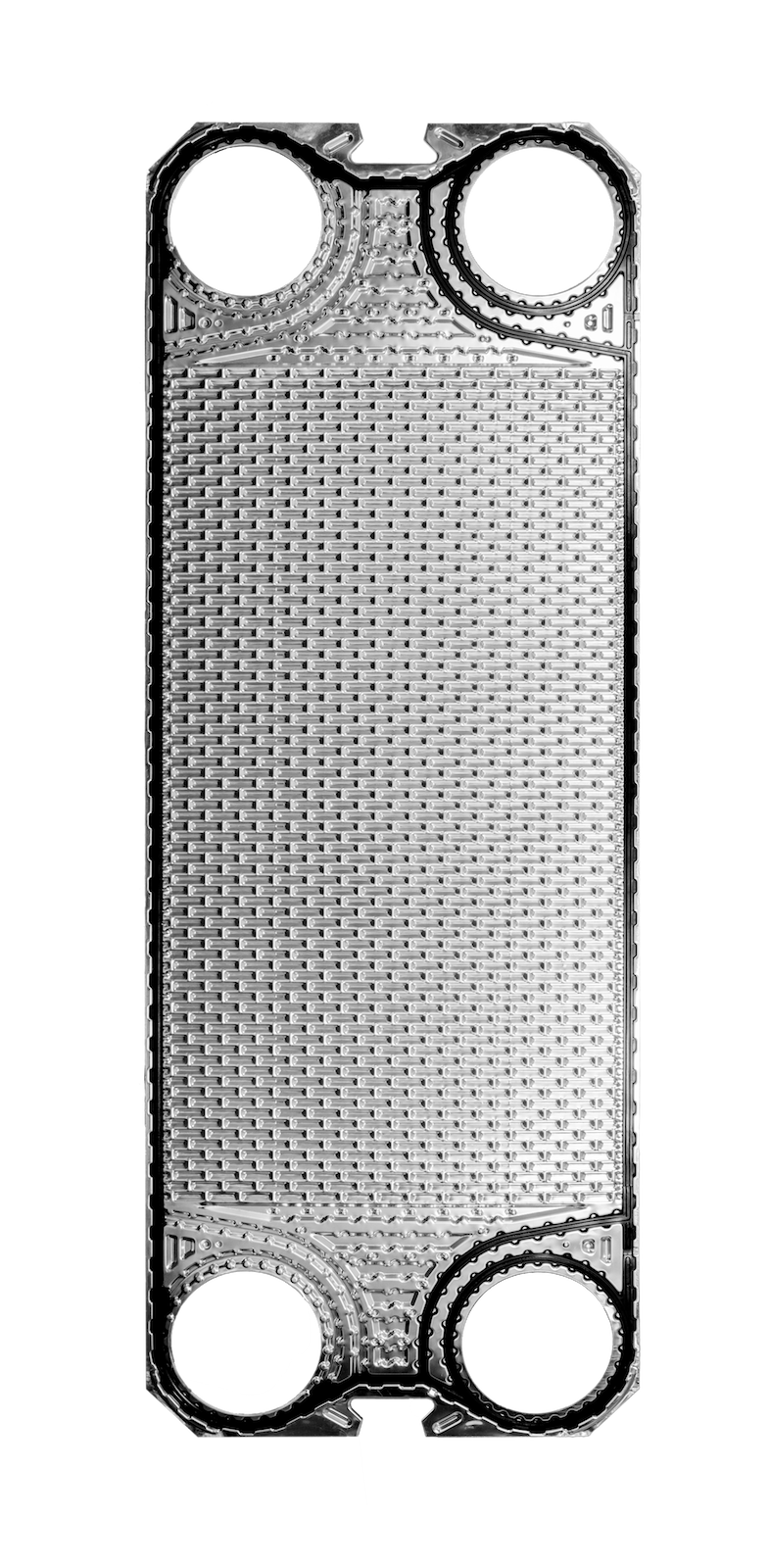

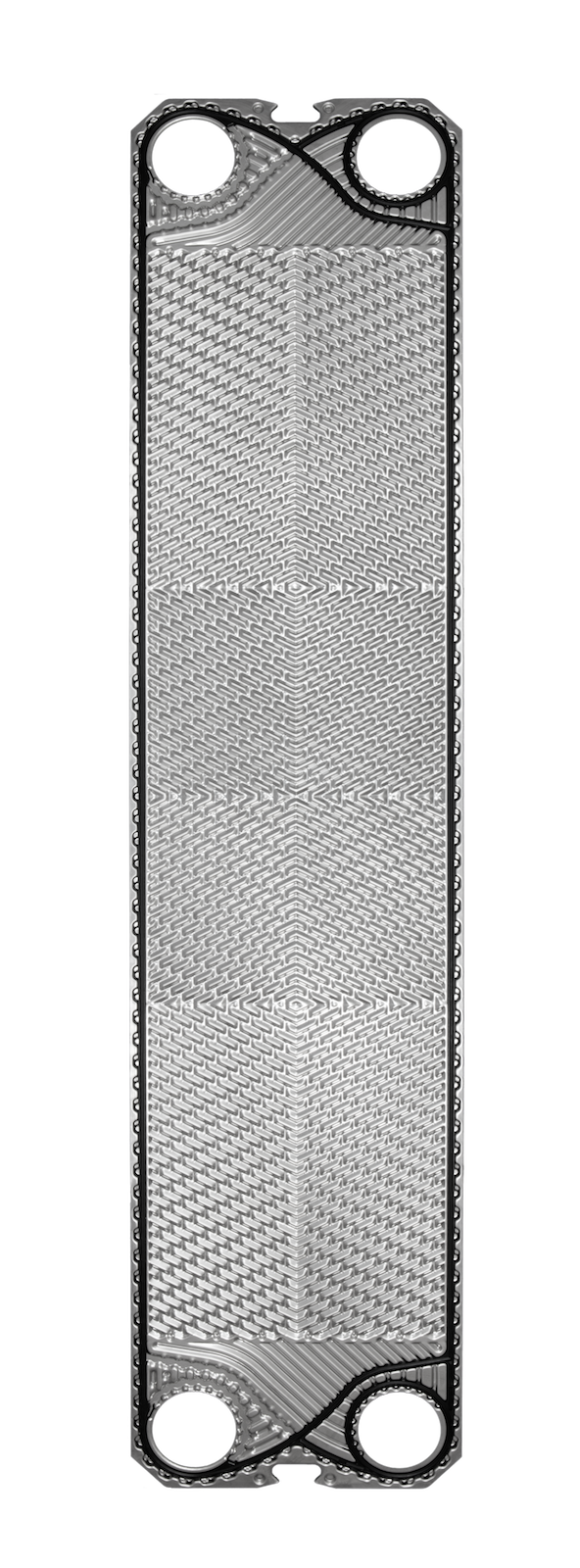

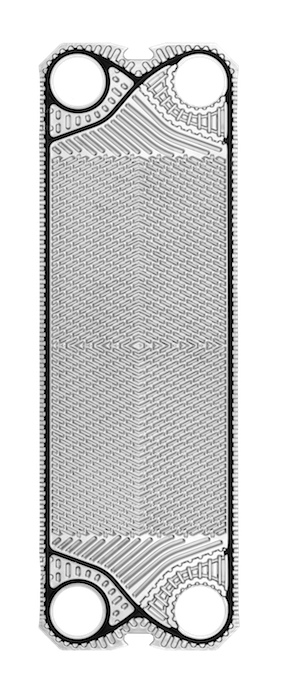

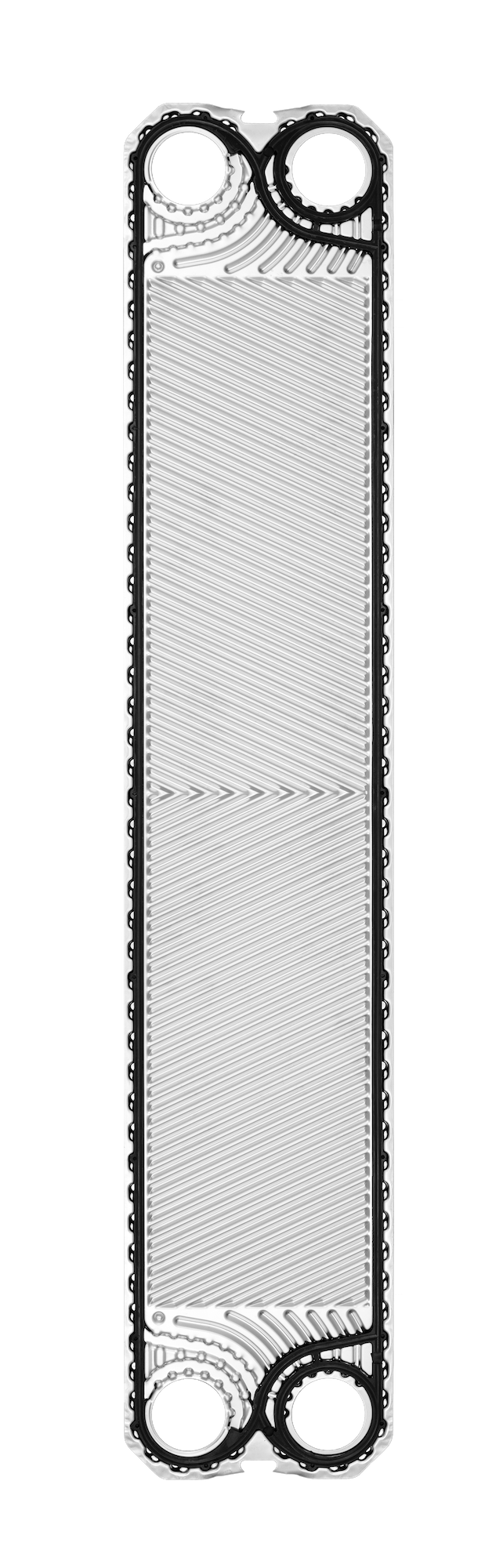

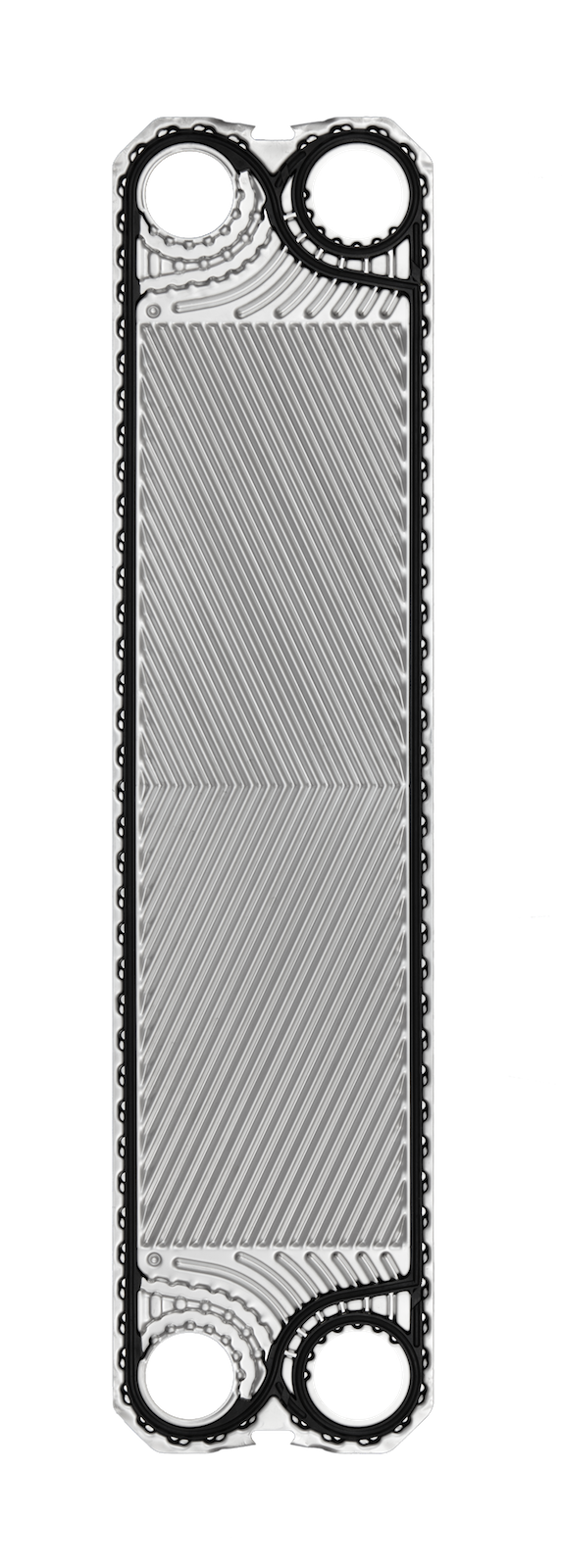

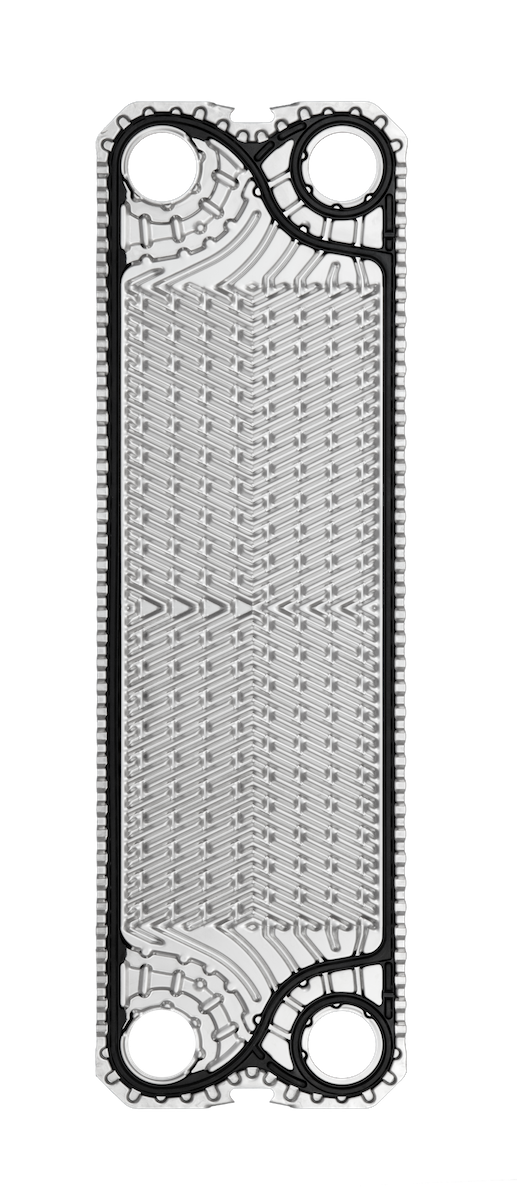

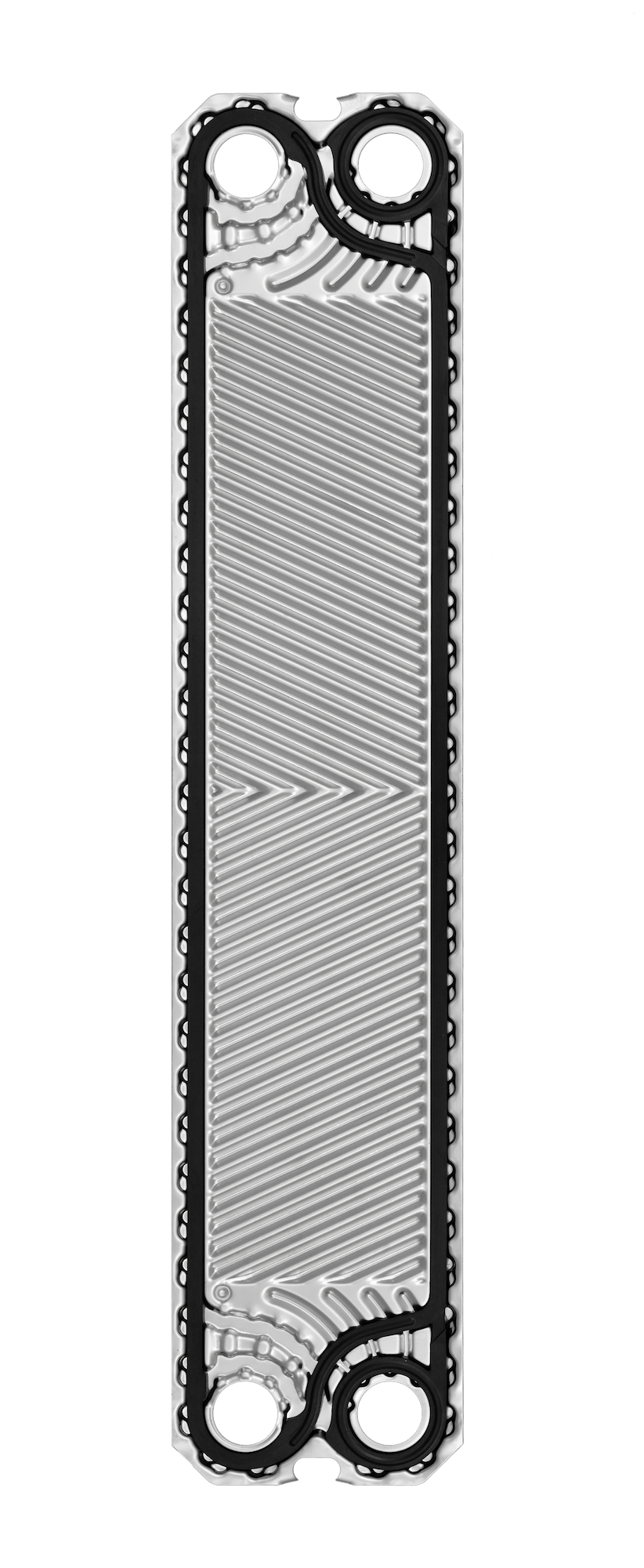

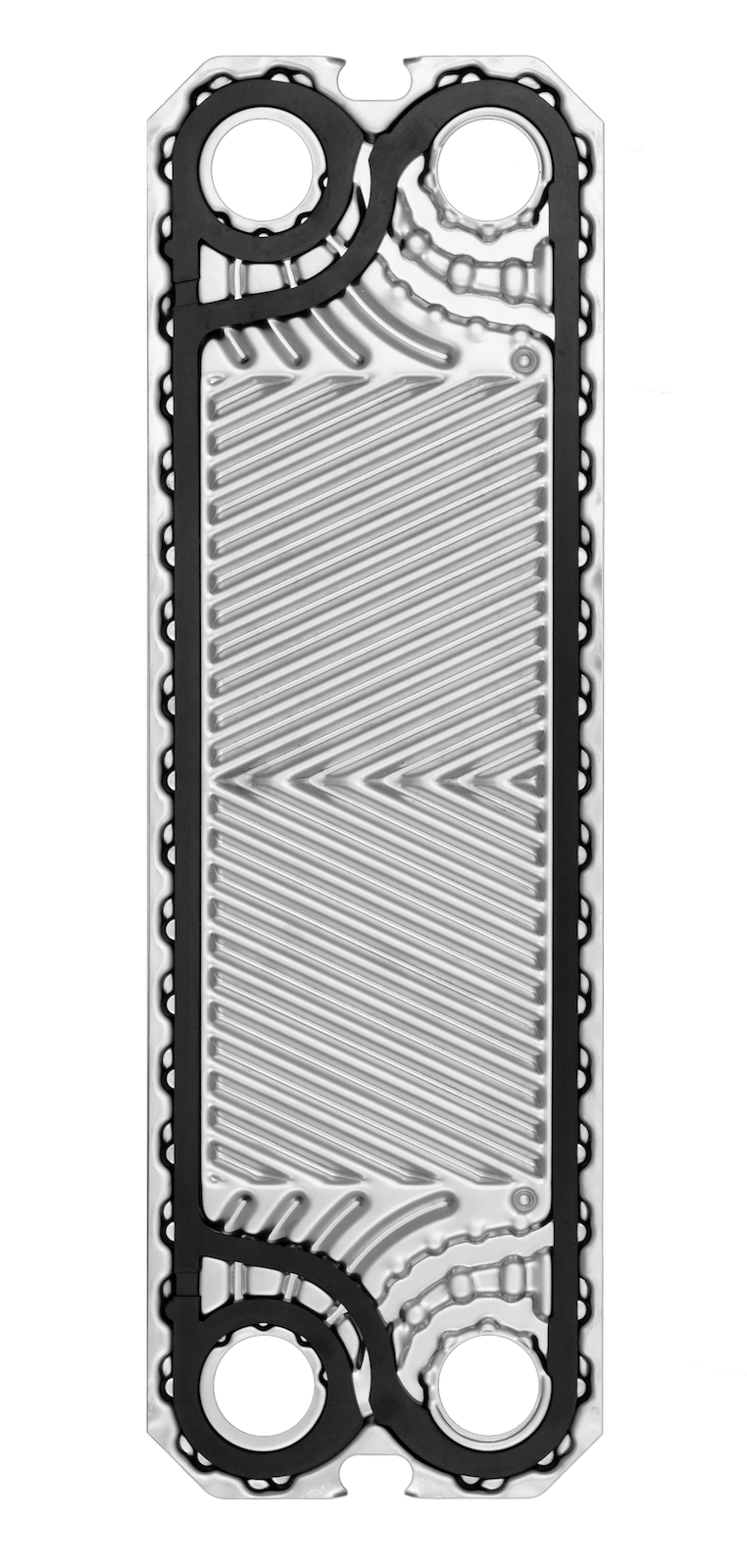

Our plates are designed by our engineers to meet any requirement of an application. The plates are produced in house with our own pressing tools and on our own presses. A very rigorous manufacturing and quality control system ensures the highest possible quality of our plates. All standard plates and special plates are made of material with various thickness and of various metal alloys in our factory in Austria.

choose from our extensive offerings!

choose from our extensive offerings!

choose from our extensive offerings!

choose from our extensive offerings!

choose from our extensive offerings!

choose from our extensive offerings!

choose from our extensive offerings!

choose from our extensive offerings!

Benefits of Fischer heat exchanger plates:

- Made to highest quality standard in the industry and the best value

- Customized design and manufacture of plates upon request

- Plates made of special material (suitable for the forming process) upon request

- Very long lifetime

- Highest degree of form stability

- Low friction surface in contact with the product

- Smooth surface to keep build up at a minimum

- Designed for gaskets to be glued in place as well as for press-in gaskets

Technical Details for our heat exchanger plates:

- Standard plates with surfaces from 0.54 square feet (0.05 square meter) to 16.15 square feet (1.5 square meter)

- Materials used: Stainless steel AISI 316L, Titanium ASTM B265-11 G1, Nickel-Alloy UNS N10276, other alloys and materials upon request

- Standard thickness of material used: 0.0236 inches (0.6 mm), 0.0325 inches (0.8 mm)

- Special thickness of material upon request

- High capacity profiles

- Free flow profiles to meet requirement of liquids containing solid particles

Request information

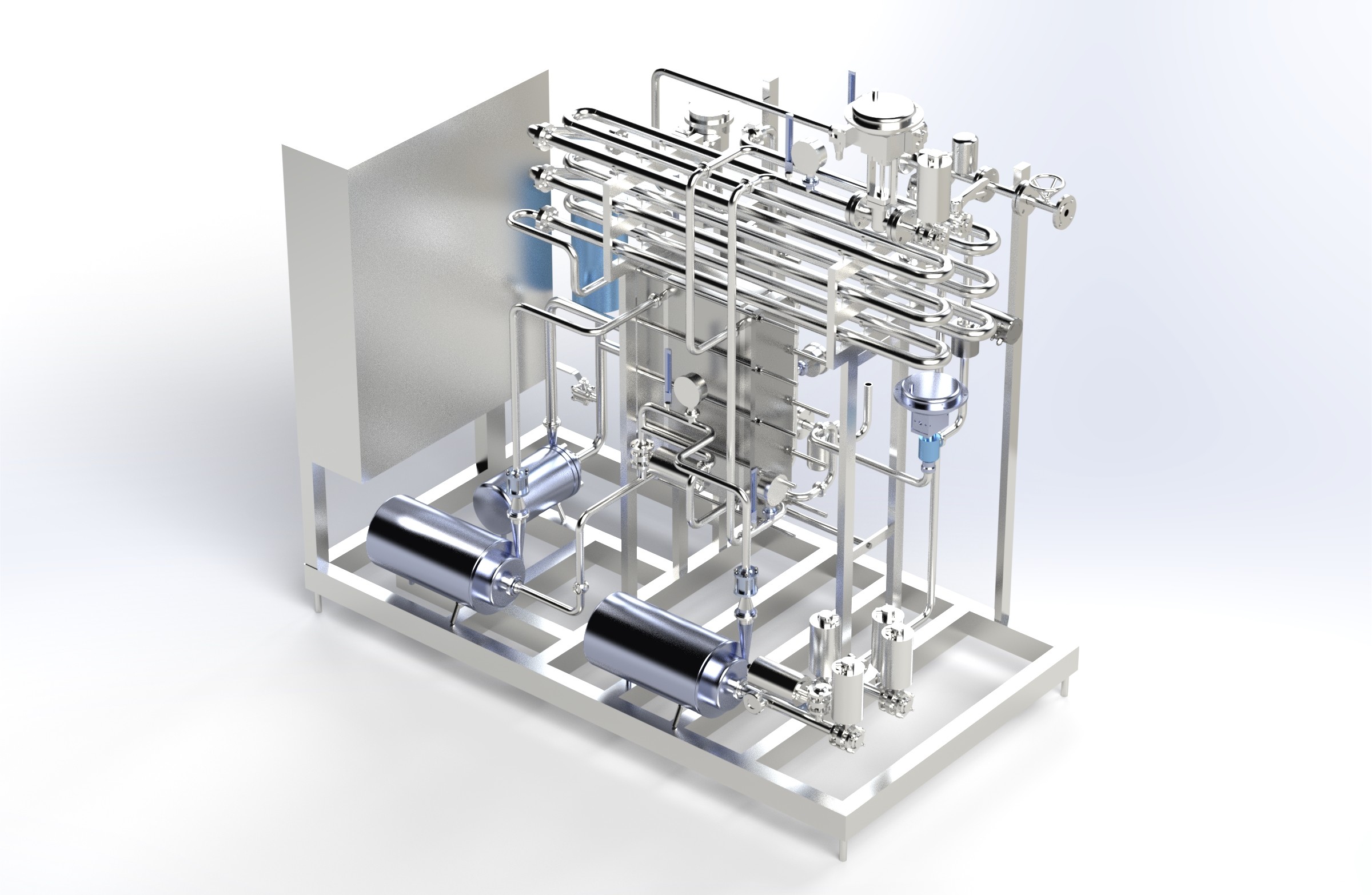

Fischer’s Plate Heat Exchanger product is developed and optimized for the food and beverage industry’s heat transfer needs, but its application is not limited to those industries. Successful applications have been in water purifying systems, desalination systems, salt production, steam condensers, and many more other applications. This is why our plate heat exchangers are one of the leading heat transfer solutions available.

Various designs of the plates allows for the selection of the optimum product flow and most efficient heat transfer. Various types of materials used for the plates and gaskets meet almost any requirements of processed products. Our plate and frame heat exchangers can be configured in many ways to optimize the use of energy and meet very tight process parameters with precision to ensure quality control.

Our qualified technical sales consultants will be happy to discuss details of your application.

Benefits of Fischer Plate Heat Exchangers:

- Food-proof materials and materials for chemically aggressive liquids

- Easy to clean, CIP compatible

- Low maintenance cost

- Long lifetime

- Various profiles of plates for different needs

Technical details for our heat exchangers:

- Special plates for steam condensation systems

- Gaskets for installation with adhesive and press in gaskets

- Plate surfaces from 0.54 square feet (0.05 square meter) to 16.15 square feet (1.5 square meter)

- Capacities up to 150,000 US Gallons / hour

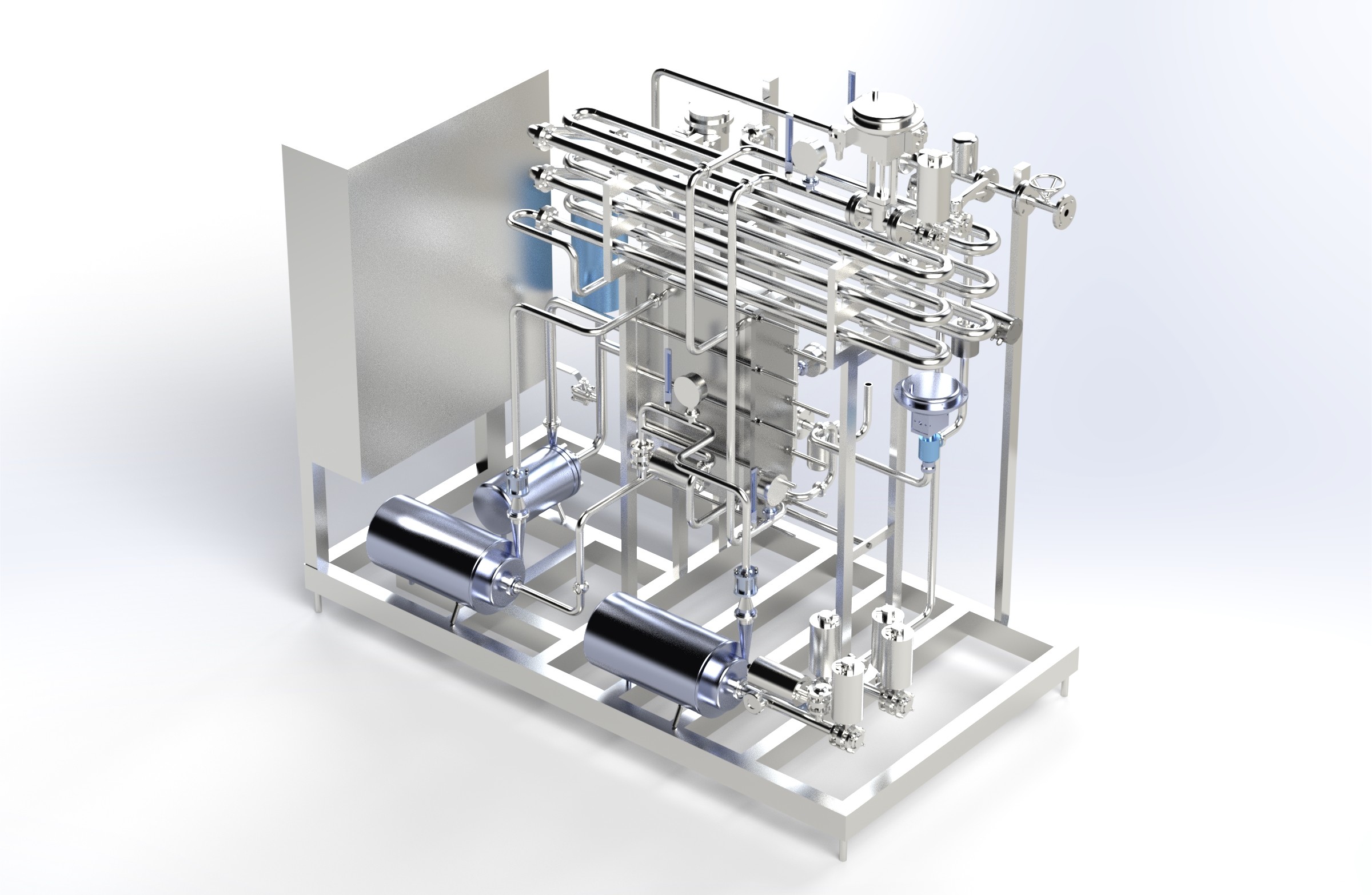

Pasteurizers for Milk, Juice, Beer

Fischer has manufactured pasteurization systems since the year 1933. The basic dairy equipment produced at that time evolved into customized, high-tech PLC-controlled pasteurization equipment meeting highest quality control standards and providing the most precise process control.

Fischer Pasteurizers can process milk for drinking, cheese, yoghurt, whey and whey concentrates, cream, beer, wine, juice, etc. Our milk pasteurizer is equipped with a sight glass for detecting leakage, with a pressure difference that prevents water from contaminating the milk. We can also meet the needs of small micro breweries with manually operated pasteurizing systems for beer production as well as the demands of industrial breweries where automation with computerized controls and data acquisition is required. Plus, our pasteurization systems can be equipped with an optional CIP system.

Our experienced experts can discuss your particular application and design the perfect system for you according to your pasteurization process. The project management team will work with you and ensure timely completion of the pasteurization machine.

Benefits of Fischer Pasteurization Equipment:

- Designed mainly for the food industry for products like milk, juice, beer, wine, etc.

- Customization of the standard design to meet your requirements

- Easy adaptation of the system to changes of production parameters

- Manual controls or fully automated systems

- Low cost of maintenance

- High quality to ensure a long lifetime

- Cleaning with CIP system integrated in the controls of the pasteurizing system

- Option to produce each system as Monoblock

- Most spare parts in stock for immediate dispatch

- Easy installation and start up at customer location by qualified service technicians

Technical Details for our Pasteurization Systems:

- Production capacity: 1,000 gal/hr to 15,000 gal/hr, larger systems on request

- Materials used: Stainless steel AISI 316L, Titanium ASTM B265-11 G1, Nickel-Alloy UNS N10276, other alloys and materials upon request

- Heating temperatures: up to 290 °F

Fischer-US, LLC

1433 Westbrook Ave

Richmond, VA 23227

USA

Email: sales@fischer-us-llc.com

Phone: +1 (804) 405-0500